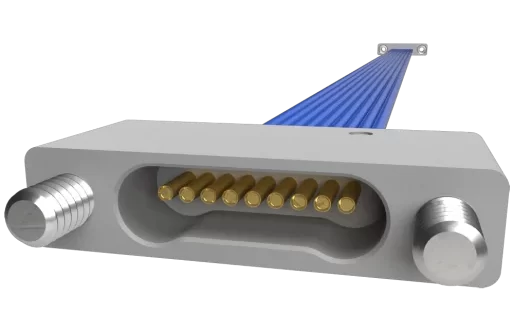

ERNI PowerTaps

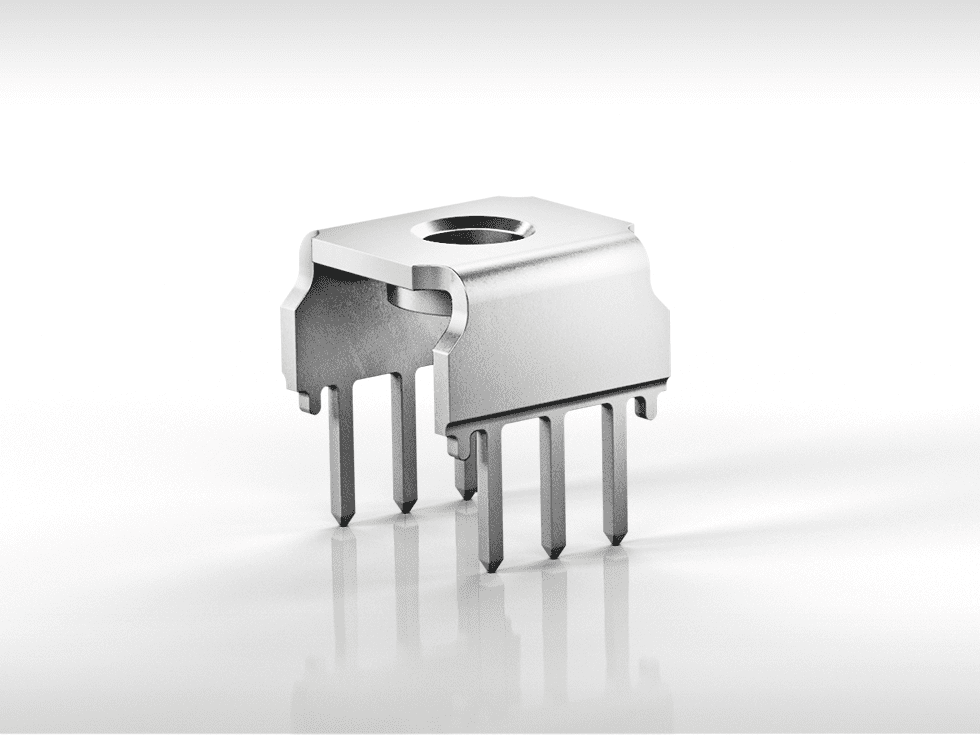

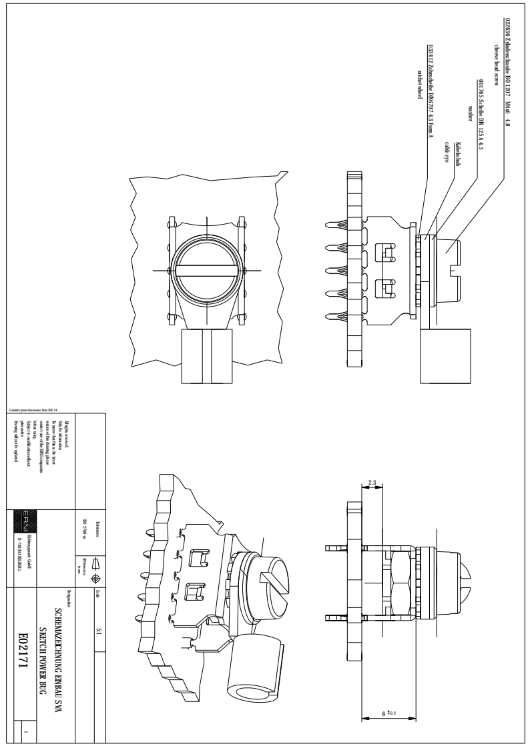

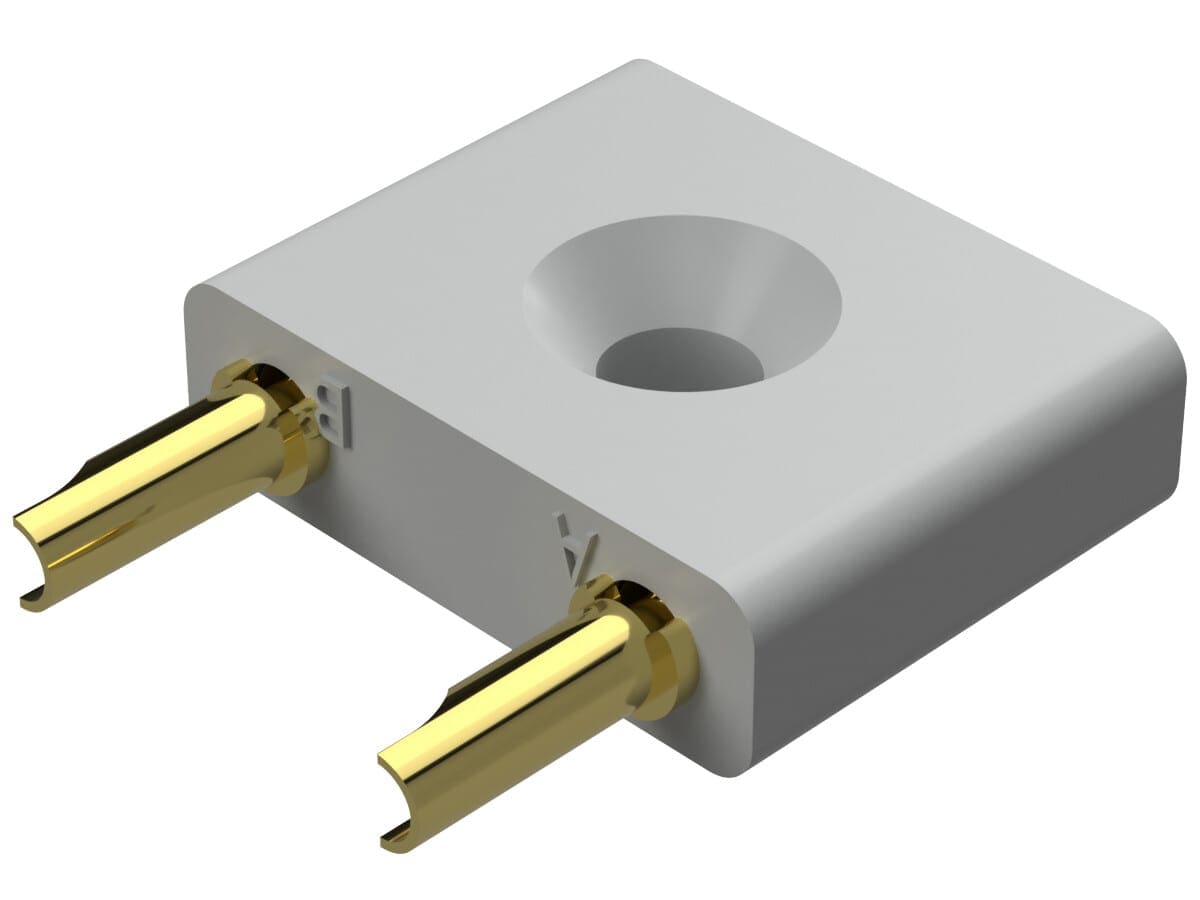

ERNI PowerTaps are PCB mount Power taps (sometimes referred to as Screw Terminals) in grids of 2.54mm, developed especially for the power supply on the PCB and backplane. They are available in various designs with six or ten connection pins and as dip solder or pressfit variants. Depending on the cable connection and PCB, operating currents up to 40 amperes can be achieved. For the variants with screw connection and angled flat connectors, the cable connection is possible with commercially available cable lugs. This provides high flexibility for the connections.

Technical Support

Jacarem has been An ERNI distributor since 2006, so our team have an abundance of knowledge to assist with your ERNI PowerTaps designs.

Applications

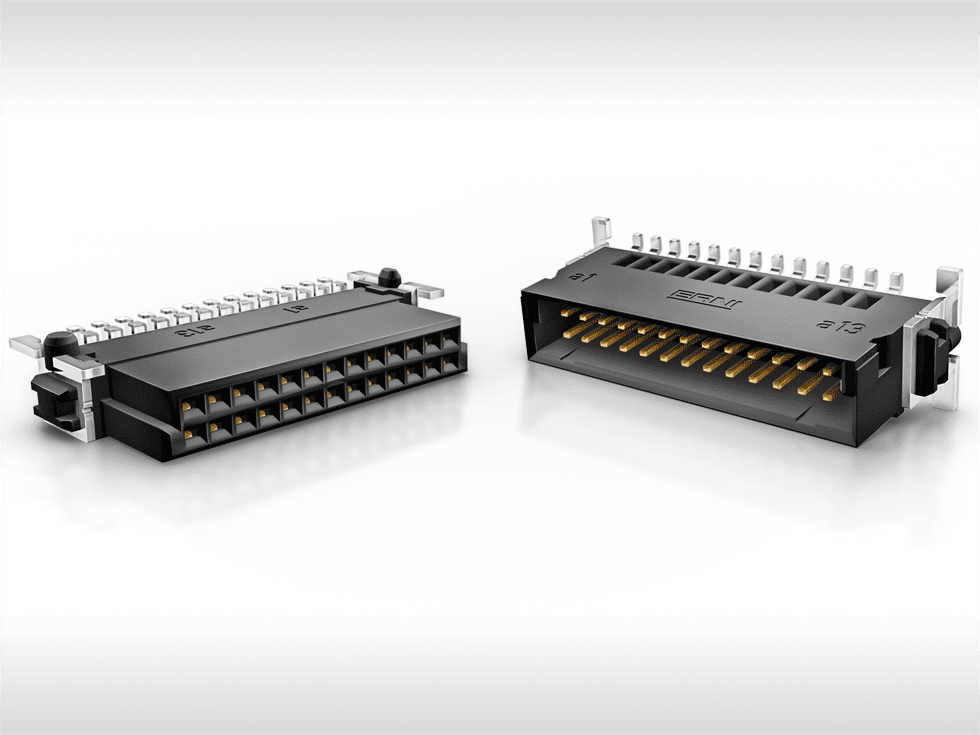

Typical ERNI PowerTaps applications can be found in the automotive area. For instance, you could utilise them in battery management systems for hybrid and electric vehicles. Furthermore, other application possibilities include power supply for PCBs in control cabinets and testing and measuring equipment. Moreover, screw terminals can also be used in energy storage for “smart home” applications.

Features

- Designed to bring power to printed circuit board applications.

- Current Rate: Up to 40 A

- 6 pin and 10 pin versions

- Two row PCB layout with 3 pins per row 6 pin and 5 pins per row 10 pin.

- Available in pressfit and solder termination.

- Connected via screw or plug-type terminals with cable lugs or flat terminal sockets

Enquire About This Product

"*" indicates required fields

For further information please contact our team of technical experts who can assist you with your ERNI PowerTaps requirements and find the best solution for your application. If you require a price or lead time, please e-mail [email protected] or phone 01494 791336.