Browse Products

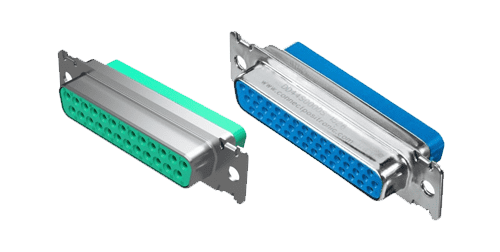

Vacuum d-sub HV connectors

Vacuum D-Sub HV connectors are available in standard and high density and are generally in stock or on a short lead time. The d-sub HV connectors are available in 9-50 pin in the standard density and 15-104 pin in the high density. All of the Subminiature D-Type HV connectors mate and are compatible with all d-sub connectors conforming to MIL-DTL-24308. The vacuum d-sub HV connectors have a non-outgassing insulator, they use precision-machined contacts and offer a minimum of 1000 mating cycles. All of our HV vacuum D-Sub connectors that we stock have stainless steel shells.

UHV PEEK D-sub Connectors

Available in male and female 9, 15, 25, 37 and 50 pin. The UHV connectors are generally in stock or on a short lead time.

Thermocouple Contacts

Are available for standard and high-density d-sub connectors. The contacts can be ordered alone or supplied with a connector. Whether you require K type thermocouple contacts, T type thermocouple contacts or E type thermocouple contacts, in 20-24awg, 22-26awg or 26-30awg, we have plenty of options.

Vacuum side d-sub backshells and air side d-sub backshells

are available generally from stock. We can supply sizes from 9 through to 104 way. The vacuum d-sub backshells have EMI/RFI shielding and have a die-cast zinc construction to maximise shielding and ruggedness. The vacuum d-sub backshells are well proportioned, to allow ample room for the internal conductors. Any unused cable openings are EMI/RFI protected using metal plugs.

For more information about vacuum d-sub HV connectors, thermocouple contacts and vacuum side d-sub backshells, please phone 01494 791336 or e-mail [email protected].